New Molten Salt Storage for the Energy Transition

Hyme is deploying a thermal energy storage solution that stores electricity in the form of high temperature heat in a molten salt.

Molten salt energy storage has been used in the Concentrated Solar Power industry for decades, and is one of the most mature and safe technologies for high temperature heat storage.

Hyme's main innovation is the salt used as a storage medium - sodium hydroxide. Its improved thermal properties enable us to reduce the cost and footprint of molten salt storage and to provide a cost-competitive and scalable pathway for decarbonization of heat and power generation.

How Hyme storage works

Charging

Electricity from renewables is converted into heat through electrical heaters. Salt from the cold tank is circulated through the heaters and heated up from 350 ºC to 700 ºC, then stored in the hot tank for up to several days.

Discharging

The energy stored in the hot tank is released on-demand by circulating the hot salt to a heat exchanger where the heat is transferred to water and turned into high temperature steam. Steam can be used directly in an industrial process or used to power a turbine and deliver electricity and heat. The cooled salt is pumped back into the cold tank until the next charging cycle.

THE GAME CHANGER

Sodium hydroxide (NaOH)

Our storage material is key to achieving our vision. Molten hydroxides have unique properties enabling cost reductions and higher efficiency.

Sustainable &

abundant

Produced from salt water

92 mio tons produced annually

No supply limitations

Improved thermal

properties

Higher efficiency

Cost reductions

Enable new applications

Safe

Non-toxic

Non-flammable

Low pressure

Melting point

318 ºC

Degradation point

1300+ ºC

Highest operational temperature

700 ºC

Heat capacity

2,1 kJ / kgK

Thermal conductivity

1,1 W / mK

Energy density

0,157 kWh / kg

OUR PATHWAY TO RELIABILITY & EFFICIENCY

Corrosion control

Our world-class team of chemistry and material science specialists are working to solve the toughest challenges related to high-temperature molten salt storage.

We have successfully developed proprietary corrosion control methods and we are now taking them from lab to large-scale systems.

BEHIND THE SCENE

What does it take to bring a new storage technology to life?

Great engineers, audacity, simulations & prototypes!

Salt test loops

We have our own salt test loops facilities to accelerate our development.

Test loops provide realistic conditions to test the thermal-hydraulic behavior of our salt as well as components and materials.

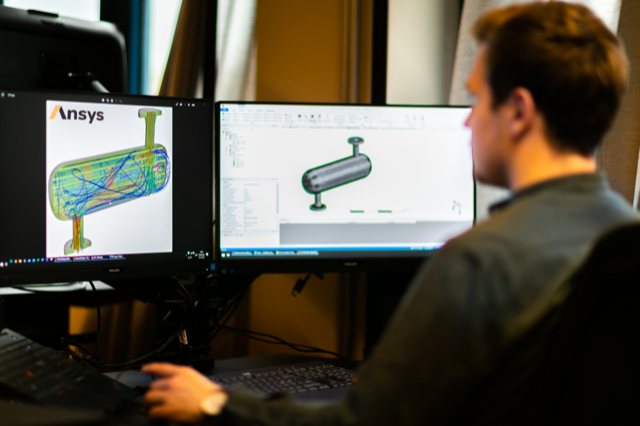

Multiphysics capabilities

We use Ansys for thermal stress analysis to increase the performance and evaluate the design of our equipment and components.